Products

One of our strengths is essentially the possibility of being able to give our customers everything they ask, having developed and produced over the years more than 70 different machines designed specifically for our work, we have both the possibility of having the constant control of the quality of our products, as well as the possibility of making the machines interact with each other in order to create infinite possible combinations of special processes

Our Fabrics

Thanks to years of experience in the sector, and to our constant efforts in research and development of new materials, we offer our customers the possibility of choosing from hundreds of different fabric bases, from the simplest and most common to the most refined and sophisticated.

All our fabrics are designed and developed specifically to be transformed through our processes, in order to minimize processing waste and to guarantee the best possible quality and stability.

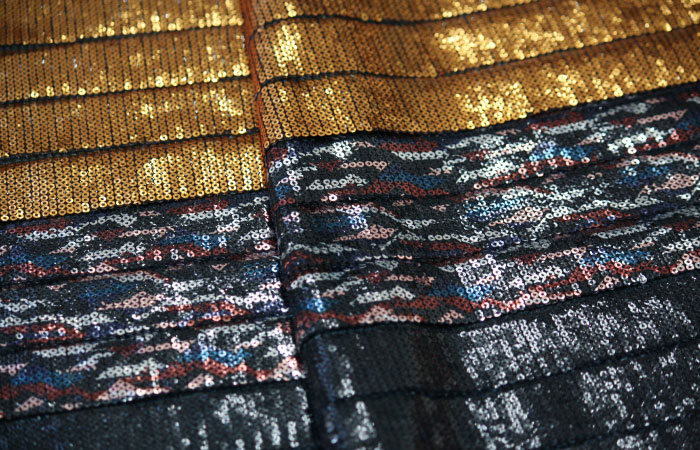

Flat Pleats

Processing carried out either by special machineries or through custom-made molds, thanks to these two different types of approach to processing, there are no limits either in size or in terms of the design to produce, we also have the possibility of creating wavy fold effects, with ruffles or with broken pleats.

Kristall

Having more than a dozen machines available to perform this kind of work, we can vary the size of the fold from 2 to 10 millimeters; it is also possible to develop flounce designs, of different sizes and ratios, depending on the needs of each client.

Smock Effect

Also this type of machinery allows absolute flexibility on the design of the pleated (plissè) design; the only constraint is the fixed 10mm ratio between the springs that produce the effect in question, but without limitations for the size of the plissè or of the frills to produce.

Soleil Sunray

The most known and ancient plissè, carried out through the insertion of a fabric panel, cut into a shape between two preformed cardboard templates, which after being closed onto themselves and carrying out a passage in an autoclave, transfer the pleating onto the fabric in a permanent manner.

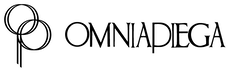

Laminations

Thanks to sophisticated machinery, specifically designed for this kind of application, we have the possibility of laminating the pleats both in roll and in piece, in this way we give our customers both the possibility of having a uniform lamination for the entire length of the roll, or for a panel, partial or placed lamination, like the one in the picture.

Mushroom Pleats

A special type of flat pleat composed of flat bidirectional pleat alternating every 1mm, creating a dense series of parallel pleat in relationship, producing a unique visual and tactile effect, giving richness and substance to every type of fabric.

Crumpled

The classic crumpled (wrinkled) effect, but with a vast possibility of changes in terms of design and development, in fact we have the possibility of creating this process in a more or less rich amount, calendered, printed, laminated, bonded, etc. giving the customer the possibility to customize the work according to their every need.

Vertical Crush

Another example of a classic crumpled effect, in this case the work remains uneven but parallel to the fabric selvedge, a wrinkle reminiscent of the historic Fortuny effect, even here, as for the crumpled, there are unlimited possibilities for the development of the processing in question .

Mixed Pleat

Work that can only be developed as a panel in which different types of pleating are superimposed in a perpendicular manner between them, giving the possibility of creating infinite cross-effects depending on the types of pleats involved in the processing.

Bark Pleat

Panel or piece processing in which several parallel plissé passages are superimposed, creating regular linear effects but at the same time creating stable and repeated irregularities for the entire length of the pleated roll.

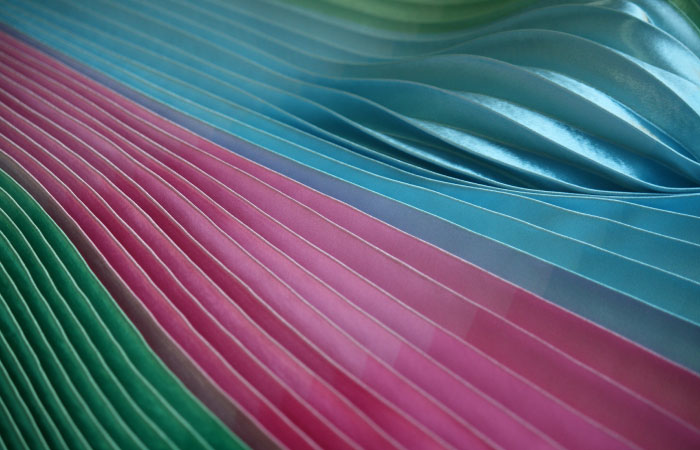

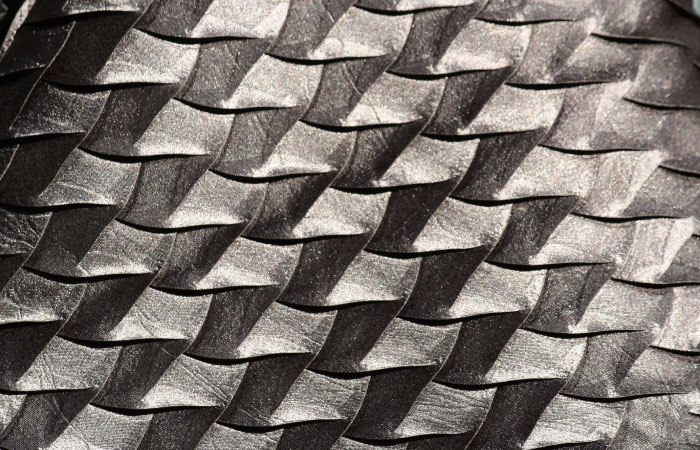

Origami

Another example of overlapping processing, here the concept of overlapping takes place by combining a typology of machine plissé with a type of pleats template, thus creating effects with a very high visual component richness, and an infinite possibility of combinations, which makes each product unique in its kind.

Fancy Sunray

The basic technique is that of the classic soleil but, using plissé templates made with special designs, unique and particular effects can be obtained, with the possibility of drawing on an archive of templates made up of hundreds of different designs.

Embossing

The Embossing panel technique, through the use of a machine developed ad hoc for polyester fabrics, we are able to obtain embossing from the depth that is two to three times greater than that given by the classic cylinder embossing, we have more than a hundred available designs, or, alternatively, with a modest cost, we have the possibility to create personalized designed printing plates.

Pinch

Panel or piece processing thanks to the matrixes that at high temperatures grip the fabric and permanently press the fold. Furthermore, by modifying the matrix and setting different transverse and longitudinal displacements, it is possible to create various designs with infinite combination possibilities.

Fancy Cardboard Design

Manual processing carried out on the panel using pre-processed cardboard templates with various types of designs which, thanks to an autoclave passage, permanently impress the fabric with pleating. Also in this case, we have the possibility to draw on our archives, choosing from hundreds of different designs, effects and formats.

Laser Cut

We have several advanced machines of different sizes, developed ad hoc for laser cutting of fabrics, thanks to this, and to specialized technicians present in our staff, we give our customers the opportunity to develop and produce customized designs, from the simplest to the most complex, also offering assistance and advice during their development.

Sublimatic printing

Even for sublimation printing, or transfer, we have different machines and an internal graphics department, so that we can offer to our customers a complete service of research, development and printing, for both plissé and on smooth fabric, drawings that are developed ad hoc on the customer’s ideas and needs, thanks to the support of our graphics, a maximum space for everyone’s creativity.

Needle punching

We have two different types of needling machines available, one for panel processing and the other for piece processing, as for the previous processes we provide the experience and the creativity of our graphics development department for the research and project of designs specifically created for our customers.